Today, I wanted to bring you one story that caught my imagination last week, about how Indian engineering could go global – not just in software, but in areas like robotics.

This past Saturday*, I got a chance to attend the annual Products Day at Ati Motors, which as I’ve mentioned in the recent past, is a startup that specialises in autonomous mobile robots for industrial applications. (*I said Friday in the audio podcast. It was Saturday, July 19.)

Ati held the event at the Indian Institute of Science’s JN Tata Auditorium. The eight-year-old company was in fact born at the institute and incubated there. Its flagship family of robots, the Sherpa, was on display at the event. Earlier in the day, Ati’s engineers demonstrated how the Sherpa Tug could pull a Mahindra Thar SUV and couple of other cars as well, all tethered one behind another.

Full stack, made-in-Bengaluru

To illustrate how far Ati has come, Founder and CEO Saurabh Chandra pointed out that this year, the Sherpa AMRs were on track to successfully execute a million autonomous missions per annum. The missions average 95 percent accuracy across challenging industrial environments worldwide.

For Chandra, this moment represented an important milestone marking the eight-year journey to prove that sophisticated, world-class robotics technology could emerge from Indian engineering talent and compete successfully in the most demanding global markets.

“Today's Ati Motors is the realization of a dream begun eight years ago, to create a truly multi-disciplinary products company that pushes the boundaries of engineering, artificial intelligence, and industrial design,” he said, speaking at the Products Day event.

Ati stands out for its full-stack approach — developing every critical component of its AMRs in-house, from navigation algorithms to mechanical design and fleet management software.

The company's engineering philosophy centres on solving real-world problems, instead of expecting customers to make significant modifications to their factory or warehouse environments. The Sherpas can function in conditions including uneven floors, outdoor environments, and areas with poor connectivity.

“For a customer in Michigan, we operated in them in snow,” CTO Arulselvan tells me in a recent interview.

As the operating environments get more challenging, “we like to say bring it on,” Chandra says. This approach has resulted in robots that can handle gradients, potholes, clutter, rain, and dust—conditions where traditional AGVs (automated guided vehicles) typically don’t do well.

The technical sophistication of Ati’s products demonstrates Indian engineering capabilities. The company is emerging as a leader in the use of 3D LiDAR-based navigation for industrial robots, enabling them to operate without infrastructure modifications such as magnetic strips or reflective markers. All autonomy processing occurs entirely onboard the robots, eliminating dependency on cloud connectivity or remote human operators.

“Our engineering team actually said if you do that, it will be a crutch that we will never get rid of,” Chandra looks back at the early decision to avoid teleoperation, in a recent interview with me. “So let us just not do it at all from the beginning. If it fails, let it be a failure that we need to fix,” rather than there being some human backup system.

This engineering discipline has paid dividends. The newly launched Sherpa 10K represents a significant technical achievement, featuring a 4.6-ton towing capacity with advanced sensor fusion combining 3D LiDAR and cameras, in-place turning for tight spaces, and the ability to operate on gradients up to 10 percent. The system integrates with existing enterprise resource planning and warehouse management systems while maintaining compliance with ISO 3691-4 safety standards.

“Our journey started with autonomous material movement, but our horizons have grown rapidly. Today, we go beyond movement: we track material, handle it and even transform it, through our AI platform: Ati Verse,” CTO Naveen Arulselvan says.

Chandra credits Bengaluru’s multidisciplinary talent pool and manufacturing ecosystem – including the emerging electric vehicle ecosystem in the country – as important factors that support rapid product iteration and real-world feedback. Very few other locations anywhere in the world have this, he says.

The city's strong manufacturing industry, though overshadowed by its IT services reputation, provides immediate access to potential customers and an ecosystem of manufacturing expertise.

Ati has deployed robots at more than 50 customers globally, including Fortune 500 companies such as Bosch, Forvia, and Hyundai. The company operates in India, the United States, Mexico, Thailand, Singapore, and Vietnam, with plans to expand into Europe and Japan.

After raising $20 million in a Series B round in January 2025, led by Walden Catalyst Ventures and NGP Capital, total funding at Ati touched approximately $37 million. This investment supports the company's expansion from deploying hundreds of robots to targeting thousands — a scaling challenge that Indian deep-tech companies like Ati will have to successfully navigate if they are to become truly global companies.

Customer confidence in Ati’s technology is reflected by the 27 percent increase in same-robot usage year-over-year, indicating not just adoption but deepening integration. This metric validates the engineering quality, as industrial customers demand high reliability before integrating automation into production processes.

Humanoid future

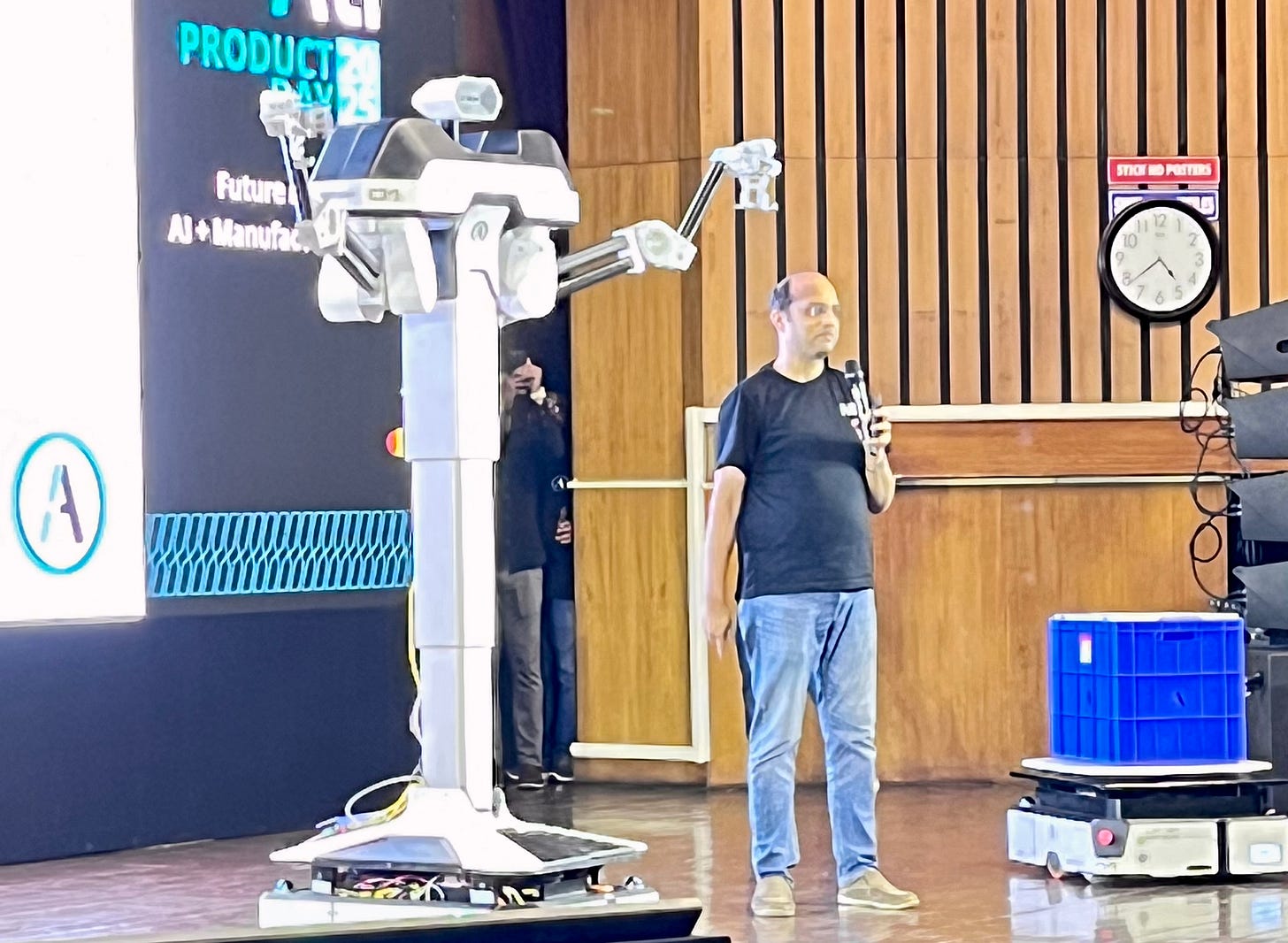

At the Products Day, a singular highlight was the surprise arrival of Mecha, Ati’s experimental humanoid robot prototype. It is now already available for research partnerships, signalling Ati’s ambitions beyond traditional material handling.

Mecha reflects a broader engineering philosophy at Ati Motors that emphasizes functionality and performance. Chandra explains that it’s less important for the humanoid to be a biped and have legs just for the sake of the form factor. In fact, Mecha came trundling out on to the stage on its own wheels.

With its arms “it doesn’t have fingers, it has tool changers,” Chandra points out.

The humanoid features best-in-class payload capabilities and carbon fibre construction with cable transmission systems, according to Ati. By offering the platform for research partnerships at $50,000, Ati aims to accelerate innovation through collaboration.

Mobile robots represent the first automation technology in manufacturing that operates without fixed boundaries — a fundamental shift that requires new operational approaches from customers. This insight drives the company's investment in customer success teams to help organizations adapt to autonomous systems that operate throughout facilities without supervision.

Arulselvan recalled a simple anecdote from a recent customer site visit: “What we like about it is that it is very predictable. Even in the third shift, it does the same,” one manager at the customer’s factory told him. Well, that’s exactly what automation is expected to achieve.

Looking ahead, Ati aims to focus on more challenging applications, combined with its full-stack technical approach and deep customer engagement. The aim is to help define industry standards rather than merely follow them. The future of industrial robotics belongs to companies that can combine technical sophistication with practical engineering discipline, and as they say in the startup world, ‘go-to-market execution.’

Share this post